Data Processing vs Artificial Intelligence at the service of energy efficiency

Manual data processing and artificial intelligence are often presented as opposites. At Dametis, our experience demonstrates that human expertise is still necessary to achieve better results with Artificial Intelligence, especially in the field of energy efficiency.

Jérémy Barrais, product manager at Dametis, talks to us about the advantages of Dametis’ data processing method compared to the traditional big or smart data method.

The difference between Big Data, Smart Data, and data models used by Dametis

Big Data: A large amount of data is provided to AI

Due to the heterogeneity of the data that makes up the big data, correlations can be found randomly. The large number of parameters involved affects the accuracy of the different correlations. Even worse, some correlations can be completely meaningless.

Correlations of this kind have already been made. An AI has notably associated the number of ice cream sales and drownings, even though the two have no cause-and-effect relationship. They simply share the same cause, the increase in beach attendance.

Another example: It has been observed that the number of toilet flushes in a southern state of the United States is proportional to the number of divorces observed in a state on the opposite side. Yet, there is no connection between these two phenomena.

Smart Data: Data is selected by theme, to focus on a functional context.

Business expertise remains essential at this stage. Our specialists at Dametis carry out on-site measurement plans, which is a fundamental element of smart data, enabling the selection of the most significant and impactful data.

Dametis Model: Data is contextualized before being analyzed by AI.

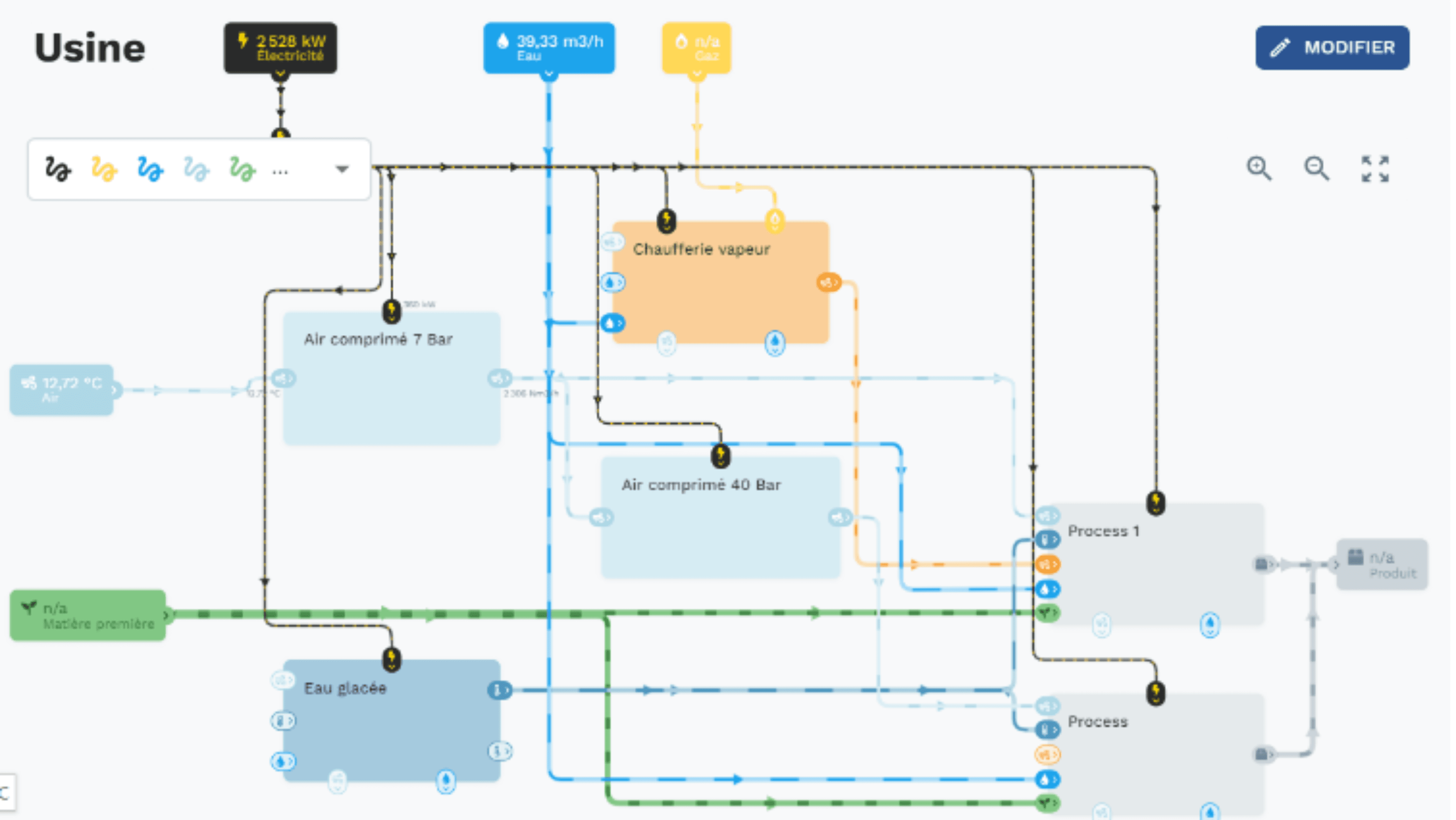

The block diagram, a tool for contextualizing the data

To do this, Dametis will first define the physical relationships between the data and thus build a “schema”.

In addition to this mesh, this data will feed into “blocks” representing the different installations of a factory (which is itself a block in its own right, made up of “child” blocks, which is at the core of our “Lego theory”).

These blocks are configured by our experts to integrate all the “business” logic. This mesh and these blocks represent our concept of the “block schema”.

The block diagram, a concept allowing for more accurate predictions

For example, the temperatures of a fluid at different stages of its circulation loop (central outlet, exchanger 1, exchanger 2 inlet, central return, etc.) will no longer be evaluated independently but rather in relation to each other. For a compressed air installation, the on/off status of the compressors, their electrical consumption, the flow rate, and the central outlet pressure are all interrelated to provide a “link” between the data.

Associating them with a block diagram representing the installation will provide additional contextual information. The data is then enriched with knowledge, known as “metadata.”

The operating conditions of each block will also be provided to offer even more information, such as operating instructions.

This contextualization in the form of a block diagram enriches the collected data and thus refines the modeling and predictions.

A model with multiple benefits

Once the model is configured by our experts, AI will use all these elements to model your entire installation, from the smallest element to the largest assembly. Many benefits result from this.

Real-time

Drift Analysis

Automatic Notifications

You receive automatic notifications as soon as data or an analysis is suspected. For example, in areas where the volume of material losses suddenly increases. Additionally, you receive alerts when there is a technical failure.