White paper 2: From Energy Performance to Environmental Performance

Today, industries are faced with a complex issue: how to boost their activity, optimize their competitiveness while considering environmental imperatives?

Industrial processes are energy-intensive, as they consume large amounts of steam, compressed air, refrigeration, etc. Therefore, the question of the energy performance of the manufacturing industry is crucial if the sector wants to succeed in its energy transition.

Energy performance is now a prerequisite. It is high time to go further and talk about environmental performance.

This is the entire subject of our new White Paper entitled:

“From Energy Performance to Environmental Performance”

We provide you with all the steps to follow and the tools necessary to succeed in your environmental performance.

The drafting of this White Paper was made possible thanks to the experts at Dametis:

Julian Aristizabal

Co-founder, CEO

Grégory Pain

International Business developer

Guillaume Lecore

Services Director

and other environmental efficiency experts:

Mathias Welschbillig

Environmental Expert

Olivier Barrault

President of ATEE Grand Ouest & CEO of Elodys International

Summary

> Chapter 1 – Energy Management

II. And to go further, Dametis proposes environmental management, not just energy

> Chapter 2 – Water Management

I. Water is a precious resource for businesses

II. Water management or clean-in-place (CIP)

III. Wastewater treatment plant (WWTP)

> Chapter 3 – Material Management

Chapter 1: Energy Management

I. What is Energy Management?

• “Energy management,” an essential implementation

Energy is invisible, omnipresent, and indispensable to a company. Electricity, gas, oil, coal are primary energy vectors; compressed air, steam, hot water, cold water, chilled water, and any cooling liquid are secondary vectors.

In a factory, energy, through these primary and/or secondary vectors, allows the transformation from one vector to another and the transformations related to processes.

Energy management is therefore simply the ability to manage this energy.

Thus, Toshiba trusted Dametis to improve its energy consumption on its Dieppe site.

• Energy efficiency: an objective and an asset to achieve for the climate and consumers

Energy represents between 1 and 5% of companies’ expenses. The impact is secondary. Yet, it is a crucial issue. “The subject of energy has become a priority for consumers with the environmental issue,” recalls Julian Aristizabal, CEO and founder of the start-up Dametis.

The Energy Transition Agency thus reminds us that energy performance is “a key element of the performance of tomorrow’s industry.”

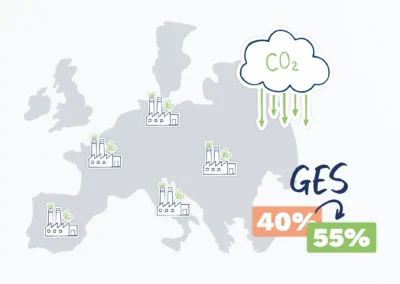

Despite a decrease in energy consumption in the industrial sector of 11% from 1990 to 2014, 40% for greenhouse gas emissions, and 50% in intensity, “the industrial sector can still improve its energy efficiency by an average of 20% by 2035.”

Certainly, solutions exist to mitigate energy consumption. There are, on the one hand, green energies, and on the other hand, the carbon offset market, which translates, for example, into low-carbon labels such as the Verified Carbon Standard or the Gold Standard. However, green energies do not yet have enough production capacity. Moreover, there are not enough projects to offset carbon emissions. “The National Low-Carbon Strategy (SNBC) provides for a compensation of around 100 MTCO2 eq/year in 2050 in French territory. Today, we emit around 430 MTCO2 eq/year in France.”

• “Energy management,” an essential implementation

II. To go further than energy performance in industry, Dametis proposes environmental performance management

• Energy management facing its limits

Facing current environmental challenges and pressure on businesses, optimizing energy in industrial sites is insufficient. Management must also be environmental.

In 2020, gross energy consumption in industry decreased by 9%, according to INSEE. Despite this decrease, progress still needs to be made, as it stands at 32.2 million tonnes of oil equivalent. Moreover, this decrease needs to be put into perspective with Covid-19. “40% of industrial establishments indicate that the consumption of at least one energy has decreased due to the health crisis,” highlights INSEE’s report.

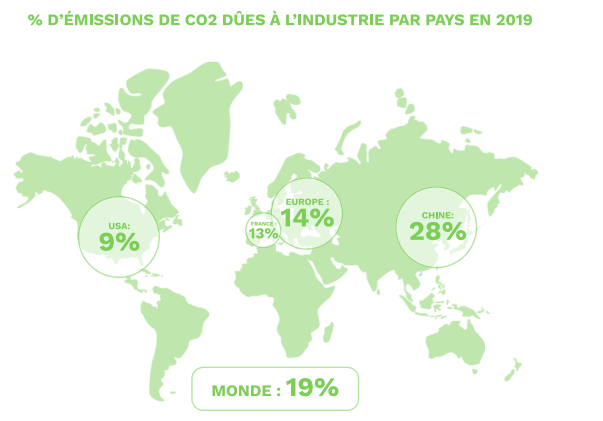

The role of companies is not negligible. In 2019, industry accounted for 19% of CO2 emissions worldwide and 13% in France. That same year was described by L’Express as the “year of climate awareness.” Indeed, climate change has become a critical issue for 94% of French people and a priority issue for 47% of them, according to a survey conducted by Ipsos for Le Parisien in 2022.

• Imagining the factory of tomorrow

“However, towards which stages should a company lead? How not to get lost in the flow of information? ” raises Olivier Barrault, president of the Technical Association Energy Environment (ATEE) in the Grand Ouest region. “In this situation, Dametis has a crucial role to play: to support in the development and implementation of this zero-carbon strategy. Especially since this start-up has the advantage of independence. It can provide neutral expertise, adapted to the needs of each.”

The energy mix is one of these responses. Customized for each company, it is a way to reduce carbon consumption while avoiding the additional cost represented by green energies.

Thinking about the factory of tomorrow involves conceiving the Process differently, as highlighted by Olivier Barrault in the presentation of the decarbonization strategy of the ATEE.

• The energy mix or environmentally-friendly energy consumption

The energy mix is “the distribution of different energy sources used for the energy consumption of a territory,” according to a definition from Planètes énergies. It is also referred to as an “energy bouquet.”

“Today, the French energy mix still depends on fossil fuels for more than 60%. To achieve its climate objectives, France must decarbonize its mix and replace fossil sources with electricity,” notes the Ministry of Ecological Transition.

There are several renewable energies:

- Solar thermal produces heat from solar radiation. This energy is “still little known in the industrial sector,” as highlighted by the Ecological Transition Agency. “

However, it is a renewable heat solution suitable for integrating into a number of heat-consuming processes. […] About 30% of the heat needs of the industry are for temperatures below 140 °C and can therefore be addressed by solar thermal.”

- Photovoltaic is the conversion of solar energy into electrical energy. This energy has been expanding in France since 2009, reaching a production of 13.6 TWh in 2014. This growth is expected to continue due to the competitiveness of this renewable energy.

- Biomass is energy produced by the heat generated by the combustion of organic matter, such as wood, plants, and agricultural or organic waste. Biomass is “the main source of renewable energy in France,” according to the Ministry of Ecological Transition. “It represents more than 55% of final energy production and significantly contributes to reducing our consumption of fossil fuels.”

- Methanization is a process for producing biogas and digestate from organic matter, such as food waste or industrial waste. The first can become biomethane, while the second can be used as fertilizer. “Producing biomethane has many advantages for the environment and territories. The waste used is local, and the energy consumption is also local. Methanization thus contributes to waste management,” notes GRDF. This process is also used in “the treatment of food waste, urban sewage sludge, and certain industrial effluents,” as highlighted by the Ecological Transition Agency.

- Green hydrogen: Green hydrogen is hydrogen produced from a renewable energy source. According to Engie, it is “one of the future levers to accelerate the transition to carbon neutrality.” In October 2021, Les Échos wrote that “green hydrogen is on its way to becoming a leading alternative energy source.”

• Energy management facing its limits

Knowing about green energies is one thing. It’s another to know which ones to use, how, in what mix, and to what extent it fits into an industrial energy performance objective.

For this, Dametis has several steps during its intervention:

1. Understanding how the factory operates. Dametis retrieves data from the factory and defines an ideal factory with the minimum environmental achievable. “This includes an objective of maintaining performance level over time and reducing consumption,” emphasizes Julian Aristizabal. “In parallel, we electrify processes because it is easier to decarbonize electricity than gas.”

2. Presenting the action plan to the industrialist. “It is the industrialist who chooses where to place the cursor of our intervention,” specifies the CEO of Dametis.

3.The energy mix. “It is simpler to decarbonize an optimized consumption,” indicates Julian Aristizabal. This mix comes after the step aimed at achieving the minimum environmental level and is proposed according to the site. Thus, “we will more easily propose a mix including methanization for a food company because it has organic waste. If a company is located in an area with abundant wood resources, we will propose a wood biomass boiler,” he explains.

Each factory is unique. The solution, precise and developed by Dametis experts, is specific to each industrial site.

Would you like to obtain and read the rest of the White Paper to know all the steps to follow and the necessary tools to succeed in your environmental performance?

Fill out the form below ↓