Energy Sobriety Is Common Sense…

The individual approach to reducing carbon emissions involves common sense and reflecting on and questioning one’s habits. In industry, it’s the same.

Are the operating methods that were relevant 20 or 30 years ago still valid in today’s environmental paradigm?

Can the manufacturing process be reviewed without destabilizing the entire production chain and within a framework of efficient and more energy-respectful change?

What is energy sobriety?

In the context of energy transition, adjusting consumption (electricity, gas, oil) and reducing environmental footprint in various areas become essential actions. In an era of overconsumption, energy sobriety invites us to rethink our consumption and operational modes to limit ourselves to actual needs.

As a true approach, its main goal is to reduce superfluous consumption to limit harmful effects on the environment.

The négaWatt association specifies that energy sobriety is achieved using four levers: [1]

-

- Convivial sobriety involves the sharing and mutual use of equipment.

- Dimensional sobriety concerns the proper sizing of equipment according to their conditions of use. This involves adapting machine operations in industries to actual needs.

- Structural sobriety consists of creating conditions within the organization of space or activities that promote consumption moderation.

- Usage sobriety focuses on the proper use of equipment to reduce consumption.

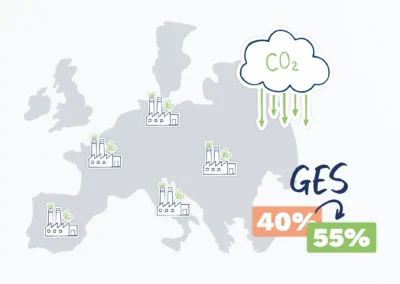

Why is energy sobriety being discussed more today?

The war between Ukraine and Russia, a significant energy supplier to Europe, has increased tension on gas and oil prices.

Additionally, France faces a decrease in electricity production due to maintenance on several of its nuclear power plants.

Faced with a risk of gas and electricity cuts this winter, the government, specifically Prime Minister Elisabeth Borne, presented her energy sobriety plan on October 6, 2022, with a clear objective: a 10% reduction in France’s consumption in two years and a 40% reduction in energy consumption by 2050.

Dametis is proud to be a signatory of the Sobriety Commitment. “Like the hummingbird, Dametis is doing its part.”

Energy sobriety in industry

According to the statistical service of the General Commission for Sustainable Development, the industrial sector consumed (in total) 312 TWh in 2021, or 17.5% of French consumption. [2] The main forms of energy used remain natural gas (37%) and electricity (36%), followed by refined petroleum products, commercial heat, and coal.

A significant share highlighting the major challenge this sector represents.

Embarking on an energy efficiency journey begins today for industries to massively reduce their environmental impact and become true actors of sustainable development in France.

Industries must implement actions to limit their consumption and achieve energy sobriety. Several simple measures can be easily applied and represent substantial savings on annual energy bills: turning off machines/devices at night, investing in less energy-intensive machines, avoiding leaving devices on standby.

Reducing energy bills is also a crucial part of energy sobriety. To lighten their bills, industries can turn to renewable energies such as biomass, geothermal, and wind power.

How to take action?

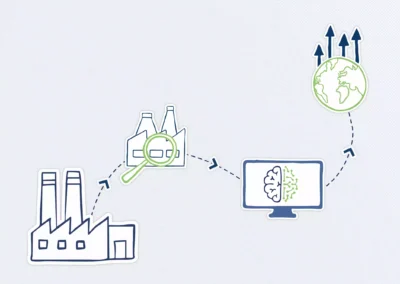

First step

- Assessing your energy consumption and uses is essential to precisely identify possible improvements.

- Establishing an action plan tailored to your company.

- Identifying the real needs of your plant, the current carbon footprint, costs, and expected results.

- Taking necessary measures to understand your plant’s operation and identify areas for improvement.

- Conducting a thorough study to propose a solution suited to your needs.

Second step

- Proposing an alternative, less energy-consuming, and more efficient solution aimed at:

- reducing your energy consumption and expenses

- engaging in an energy sobriety approach

- Supporting you throughout the process by implementing the chosen technical and material solutions.

Third step

- Providing regular reports on the commitments made to ensure the solution’s proper functioning.

- Remote monitoring of your installations’ consumption evolution.

Client cases illustrating energy sobriety

Dametis, alongside alginate producers, to optimize their production

Algae production activity

The existing situation: Dametis worked for a German alginate-producing industry based in Brittany, operating in a niche market. Made from algae, the production of alginate, later used for food, cosmetic, or pharmaceutical purposes, is a complex process requiring heating and cooling the material multiple times.

Step 1: The reflection. Instead of multiplying the steps that each require a significant volume of water to be heated or cooled, we confront the two water masses: the one at 100°C and the one at 10°C, to recover the energy from one to cool the other.

Step 2: Then, we assist in replacing the existing equipment with the one recommended after the analysis to aim for energy efficiency.

Step 3: Finally, we conduct a review without which the approach would make no sense. The work team revisits the initial data, the commitments made at the beginning of the project, and evaluates the results of the new installation.

Guillaume Lecore, Services Director at Dametis, adds: “It’s a particularly interesting case at Dametis because rather than simply implementing a heat installation on a refrigeration installation, we went further into the process to set up something quite unique with an innovative process breaking the verticality of this type of industry.”

Dametis, alongside food producers, to optimize their production

Onion production activity

The existing situation: A food company producing onions wants to review its gas burner drying process to optimize its yield, avoid losses, and reduce energy costs in a context where prices are often under pressure and energy transition must be imminent. The problem is this: when onions are harvested, they are wet. To preserve them, the moisture needs to be removed, so they must be dried at a precise temperature not exceeding 22°C to avoid losing their properties and achieving a counterproductive effect that would cause rot. Once dry, however, they can be stored for a long time at 4°C.

Step 1: After a preliminary analysis of the environment and the existing setup, air dehumidification was chosen as the drying method. The Dametis team recommended using outside air to blow on the onions to dry them. This air can then be cooled by a refrigeration installation and reheated using the energy recovered from the cooling action to finally be blown on the onions. It can then capture much more moisture, allowing for efficient drying.

The solution: Implementing a refrigeration installation that has much better performance than the previously used gas, and runs on electricity, thus having a much better carbon impact.

Guillaume Lecore, Services Director at Dametis, adds: “This solution has recently been implemented, we will do a detailed review remotely, but from the outset, replacing gas with an electric installation reduces CO2 emissions by around 75 to 80%.”

[1] L’association négaWatt précise que la sobriété énergétique s’atteint à l’aide à de 4 leviers

Blog

Discover our latest articles

Webinar #5: How Etria optimizes its energy usage, reduces costs, and calculates the carbon footprint of its finished products