The Economic and Environmental Benefits of Methanization: Insights from Our Experts

Wastewater treatment plants represent a significant cost for companies. With an innovative industrial methanization process, Dametis and its partners turn this challenge into an opportunity. The ongoing project with a food processing company thus generates profits while reducing environmental impact.

“Based on the collected data, we proposed installing a methanization module,” explains Sébastien Papouin, Technical Director of Energy and co-founder of Dametis. The start-up has been working with a major industrial group since spring 2022. It is supported by its network of experts, such as EGIS, an international consulting and engineering group specializing in the environment; SET Environnement, a study office; and Mathias Welschbillig, a technical expert on the environment and particularly wastewater.

The future project includes, besides the methanization module, a new wastewater treatment plant (WWTP). “The company noted an excessive amount of effluents discharged by their current wastewater treatment plant. However, considering the presence of organic matter, it seemed wise to install a methanization module alongside the WWTP,” details Sébastien Papouin. “This is an innovation for the next forty years,” emphasizes Yann Balem, energy project manager and study engineer at Dametis.

Biogas, a Green Energy

Methanization is a biological phenomenon, based on “the degradation of organic matter by microorganisms” [1], explain the experts from the Agency for Ecological Transition. This fermentation produces biogas, mainly composed of methane and carbon dioxide. “An industrial methanization project represents a certain cost. However, it is an investment whose expenses are amortized,” adds Sébastien Papouin. Indeed, the benefits of this installation are economic. The biogas purified into biomethane can be sold to GRDF or reused internally. “The company thus creates its own energy source,” summarizes our expert.

Indirectly, this reduces the use of the wastewater treatment plant. The cost of its operation, in terms of energy and labor, is lower. Moreover, the amount of sludge is halved thanks to the fermentation process. Thus, there is less waste. The discharged water is of better quality and the treated water can be reused. “We can thus halve a factory’s water consumption,” adds Yann Balem, project manager. Finally, the sludge from methanization can be sold to farmers as fertilizer. “Thus, the waste, besides being reduced, becomes a product. It’s a virtuous circle,” continues the engineer.

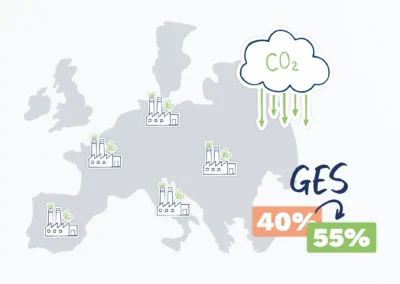

The interest is also environmental. As the Ministry of Ecology reminds, “the biogas sector

fully contributes to the objectives of the energy transition for green growth, namely the development of renewable energies, the reduction of greenhouse gas emissions, and the development of a circular economy with the valorization of digestate from methanization in agriculture.” [2] Thus, the optimization is both economic and environmental. “This biogas, produced internally, emits ten times less CO2 than imported natural gas. 1 kW of biogas consumed locally is 1 kW of natural gas not used.

This also increases the resilience of a territory and a company,” specifies Yann Balem.

How Does Methanization Work?

The methanization circuit includes an additional basin, smaller than the buffer basin. After these basins, the effluents are directed to a physico-chemical flotation unit. The addition of reagents allows for the separation between dirty water, which goes to the WWTP, and sludge, which is directed to the digester. Material losses and waste are also included in this reactor where fermentation occurs. During this digestion, microorganisms will break down the organic and biodegradable matter, thanks, notably, to the absence of oxygen in this module. The biogas is then recovered. The digested sludge is concentrated, stored, and then valorized by agriculture. As for the dirty water sent to the WWTP, it will be recovered by the clarifier from which clean water will emerge.

A Single Point of Contact for Your Methanization Projects

“Currently, we are in the pre-project phase. This concerns the regulatory aspect,”

specifies Yann Balem. “The dossier is more complex because the procedure for classified installations for environmental protection (ICPE), to be submitted to the prefecture, also concerns the methanization project.” Dametis supports the client and builds this environmental authorization request (DDAE). “For this, Dametis has surrounded itself with experts, namely the study offices SET Environnement and GES.”

Two distinct phases are then carried out. One concerns the new WWTP, with the transfer of water, the buffer basin, physico-chemical, biological, and tertiary treatment. The other focuses on the methanizer and hygienization. “There is no subcontractor mastering both methanization and WWTP,” explains Yann. “Dametis is therefore equivalent to the conductor. From the call for tenders to the analysis of files, through project monitoring, we are the sole point of contact for our client.”

The start-up thus plays a crucial role in advising, designing, and implementing this large-scale project. A service that is all the more important with the current

rise in energy costs [3] and the increase in water prices starting in 2023 [4].

To learn more about the methanization process and how to integrate green energy projects, contact Dametis, and our experts will assist you in your efforts.

Sources:

[1] https://www.insee.fr/en/statistiques/6801713

[2] https://www.lexpress.fr/environnement/inflation-pourquoi-le-prix-de-leau-augmente-t-il-aussi-en-2023-

SF7CK2PKQBHBFBYJBHNRRVNDRA/#:~:text=Le%20prix%20du%20m%C3%A8tre%20cube,agglom%C3%A9rations%20de%20France%20en%202023.

[3] https://expertises.ademe.fr/economie-circulaire/dechets/passer-a-laction/valorisation-

organique/methanisation#:~:text=Qu’est%2Dce%20que%20la,qui%20est%20une%20r%C3%A9action%20a%C3 %A9robie

[4] www.ecologie.gouv.fr/biogaz

Blog

Discover our latest articles

Webinar #5: How Etria optimizes its energy usage, reduces costs, and calculates the carbon footprint of its finished products