AI at the Service of Reducing Energy Consumption

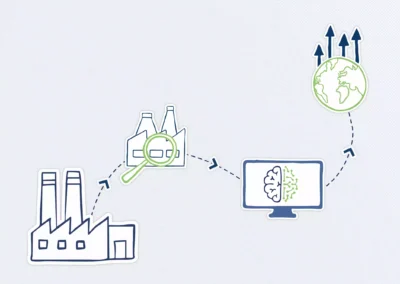

Today, artificial intelligence is at the heart of energy savings for companies. We create virtual duplicates of your machines, called digital twins, to identify areas where energy and environmental efficiency can be improved.

Nicolas Duran, CTO of Dametis, provides some examples of production optimizations using our scenario modeling technologies.

Measuring with AI to Avoid Overconsumption of Energy

The Dametis global solution addresses thousands of scenarios on the path to the Minimum Achievable Energy. Let’s be concrete. It allows creating “virtual blocks” identical to the infrastructures in the field (similar to digital twins), simulating an ideal operation for this plant based on multiple variables and needs, to visualize where the plant can progress in terms of environmental transition. Where humans cannot be omniscient, the MyDametis platform effectively and instantly identifies and alerts teams about improvement levers if the installation is not optimal.

These improvement levers can take various forms, such as:

– Renovating machines,

– Limiting unproductive energy losses,

– Training your employees to use available tools more efficiently.

Optimizing Industrial Processes with Artificial Intelligence

Monitoring the Evolution of Your Business’s Energy Consumption

Staying on Track with Energy and Environmental Transition

Over time, teams grow, factories invest and renew themselves… It becomes important to control environmental consumption to manage costs and limit the carbon footprint. Our calculation systems make it easier to visualize these changes and align them with actual needs to effectively re-evaluate the existing setup and enhance performance.

Detecting Potential Anomalies

Modeling to Verify the Proper Functioning of a Sensor Network

The possibilities are immense with Artificial Intelligence: energy is a resource we can work on in decarbonization, but the analyzed data must be correct. One possible application is using it to identify potential faults in data reporting, linked to a malfunction or failure of certain sensors.

Artificial Intelligence for Reducing Energy Consumption, Reserved for Businesses and Communities

Modeling and artificial intelligence themselves consume energy. For their recommendations to serve the energy transition, they must enable significant energy savings. This is easily achievable for large companies and communities, but the process would not be cost-effective on a household scale.

Reducing Your Company’s Energy Consumption with Artificial Intelligence

There are many ways to use artificial intelligence to reduce energy consumption. Opportunities are not always easy to detect internally. That’s why Dametis assists you: contact us to discuss your installations and needs. Our experts know from experience where and how to integrate it to achieve real energy savings and will advise you on effective implementation.