Energy Consumption Hotspots in the Agri-Food Industry

The agri-food industry involves high energy consumption, particularly for implementing the processes of transforming and packaging products.

Energy consumption is especially linked to heating, cooling, and hot water production. In this article, we will see that other activities are also very energy-intensive.

To reduce its energy consumption, the agri-food industry can adopt various measures such as improving the energy efficiency of machines and processes or using renewable energy sources…

A Higher Tonne of Oil Equivalent: A Synonym for More Harmful Energy?

How Is Energy Consumption Evolving in the Agri-Food Industry?

Each year, production processes are improved, and renewable energies are becoming increasingly accessible and easy to use in businesses. This leads to a gradual decrease in consumption in the industry. Since 2005, the consumption of industries with more than 20 employees in France has decreased by 20%, according to the INSEE website.

On the other hand, the agri-food industry lags behind, as its energy consumption has only decreased by 7% (10% with equivalent production).

However, most of this energy saving occurred between 2008 and 2009, when the industry’s gross consumption dropped from 42.26 million TOE to 36.5 million TOE. Also note that in 2005, we started at 44 million TOE, whereas the latest figures from 2019 report 35.1 million TOE.

While the figures are encouraging, we must remain clear-sighted as the reduction in energy consumption in the industry has been largely driven by:

– a decrease in production due to the 2009 crisis

– a decrease in the number of industries in France due to offshoring

Which agri-food industries are the most energy-intensive and what solutions can be implemented to significantly reduce their consumption?

The Most Energy-Intensive Agri-Food Industries

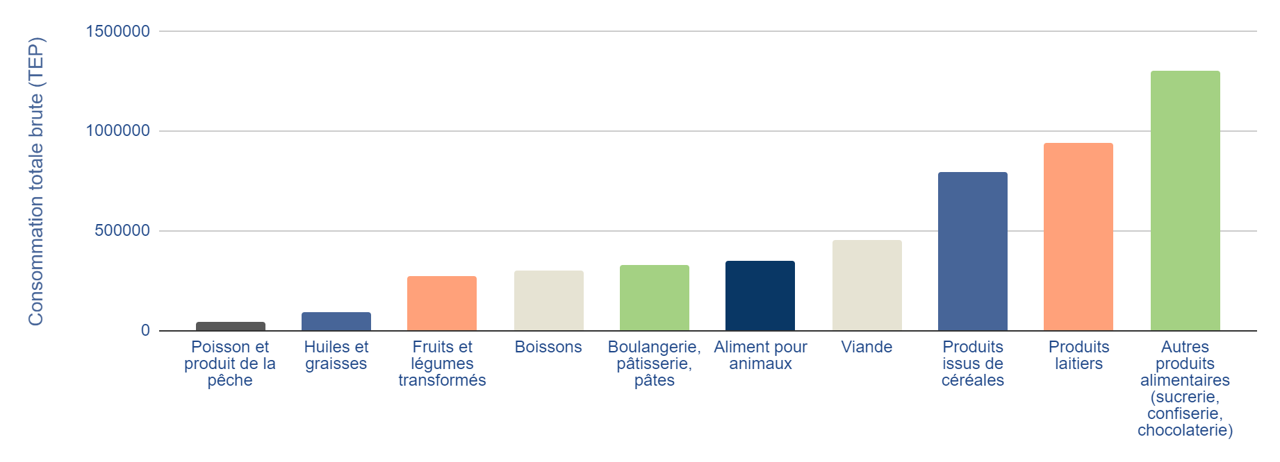

In France, the agri-food industries with the highest total gross consumption (TOE) are those producing confectionery, dairy products, and cereal products like flour.

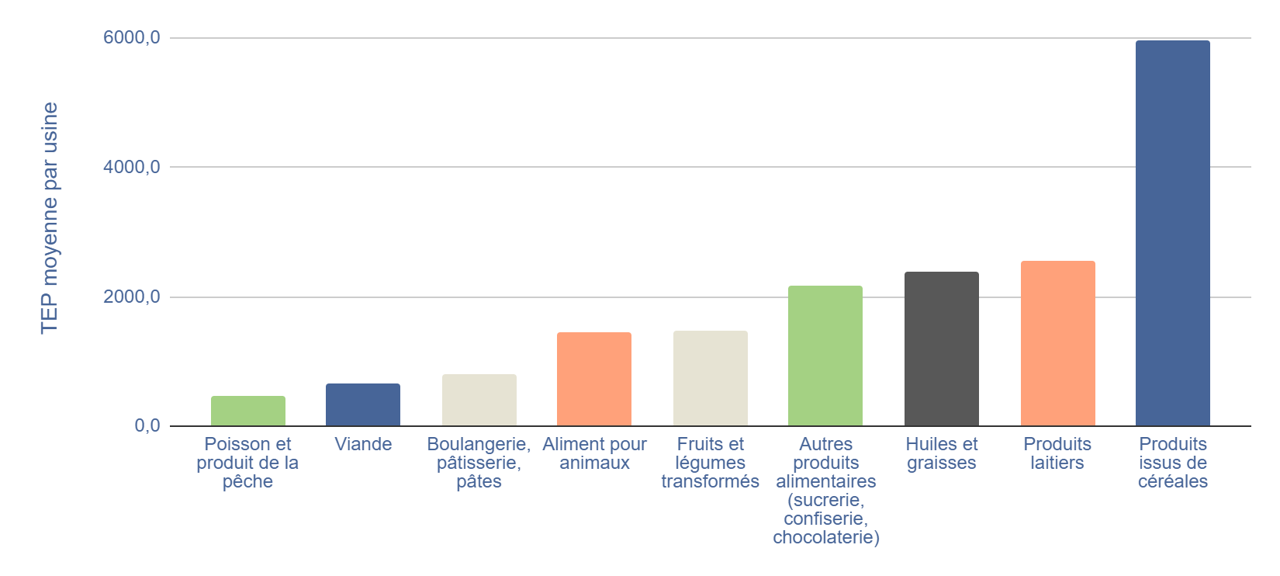

In France, the average TOE per factory is highest in agri-food industries specializing in cereal products. This industry is followed by dairy producers. Note that the average consumption of a single meat producer is among the lowest in the agri-food industry.

(*) This data is sourced from Agreste, Figures & Data No. 2022-10, published in August 2022. For more information, click here.

Energy Consumption Hotspots

Depending on the products sold, energy consumption and carbon impact vary. Here are the hotspots of energy consumption:

- Transformation Processes: The most energy-consuming industries are those of sugar and starch production. These industries involve significant transformation of raw materials, which requires extensive transport and long production chains with energy-intensive industrial equipment and processes.

- Transport Methods: Transport represents 29% of CO2 emissions in France and is an integral part of the industry. Products transported by truck, container ship, or even by plane, especially for some fruits and vegetables, increase both your costs and energy impact.

- Storage Constraints: Some products require specific storage conditions. Refrigerated trucks and warehouses, humidity regulation, and other measures require additional energy.

- Quantities Produced: Logically, the more an industry produces, the more active its machines are, the more it stores, and the more it needs to transport raw materials and deliver finished products.

There are many other factors of energy consumption. The above enumeration includes some examples where concrete action is possible, especially through the audit and advice of Dametis experts.

What Are the Levers for Reducing Energy Consumption in the Agri-Food Industry?

1. Use of More Energy-Efficient Equipment: Using more efficient and energy-saving equipment can help reduce costs and energy consumption.

2. Optimizing Existing Processes: Even minor automation adjustments can make a significant difference.

3. Implementing Energy Sobriety Actions: Small actions, such as placing signs on light switches and not leaving machines on standby, add up to a significant saving.

4. Using More Efficient Energy Management: Energy management systems (EMS) can help businesses monitor and reduce their energy consumption.

5. Using Information and Communication Technologies (ICT): ICT can be used to control and monitor energy consumption and to implement energy efficiency plans.

6. Using Advanced Technologies: The use of advanced technologies can contribute to reducing energy consumption.

7. Using Renewable Energy Sources: The use of renewable energy sources, such as solar and wind energy, can reduce energy consumption.

Dametis helps you find concrete methods to reduce your emissions and energy costs while maintaining or improving your productivity. Whether you already have ideas or seek a complete audit of your business, our experts can advise you from strategy development to implementation.

Blog

Discover our latest articles

Webinar #5: How Etria optimizes its energy usage, reduces costs, and calculates the carbon footprint of its finished products